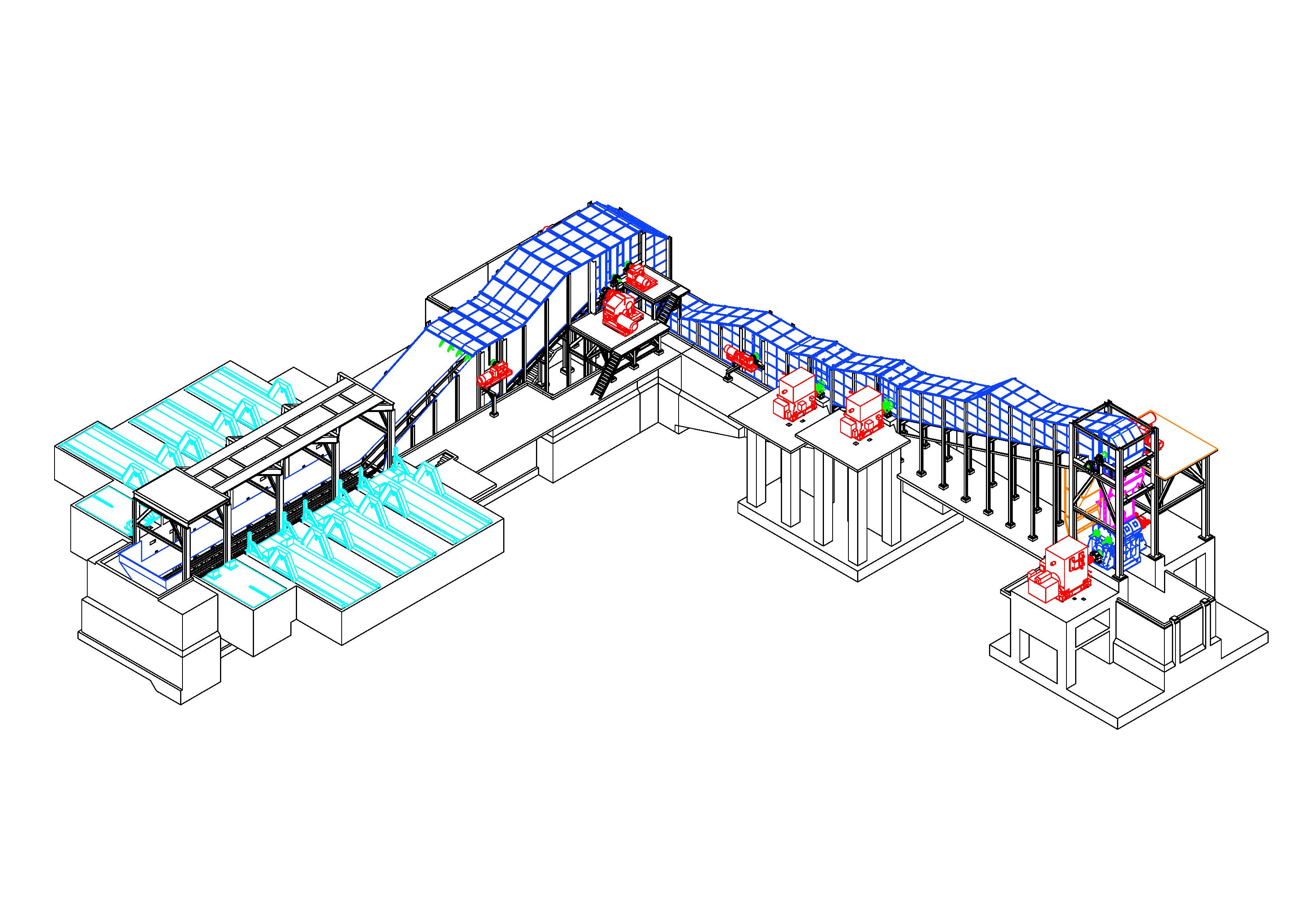

EPCC / EPC

Cane Receiving Station via Hydraulic operated Turck Tipper

Cane Handling & Sand Removal Station

Cane Preparation via Cane Cutter

Heavy Duty Swing Hammer Shredder with Feeder

Juice Extraction via Mill Train

Juice Handling via Variable Flow Pump

Separation of cush-cush Bane Bagasse by Rotary Screen

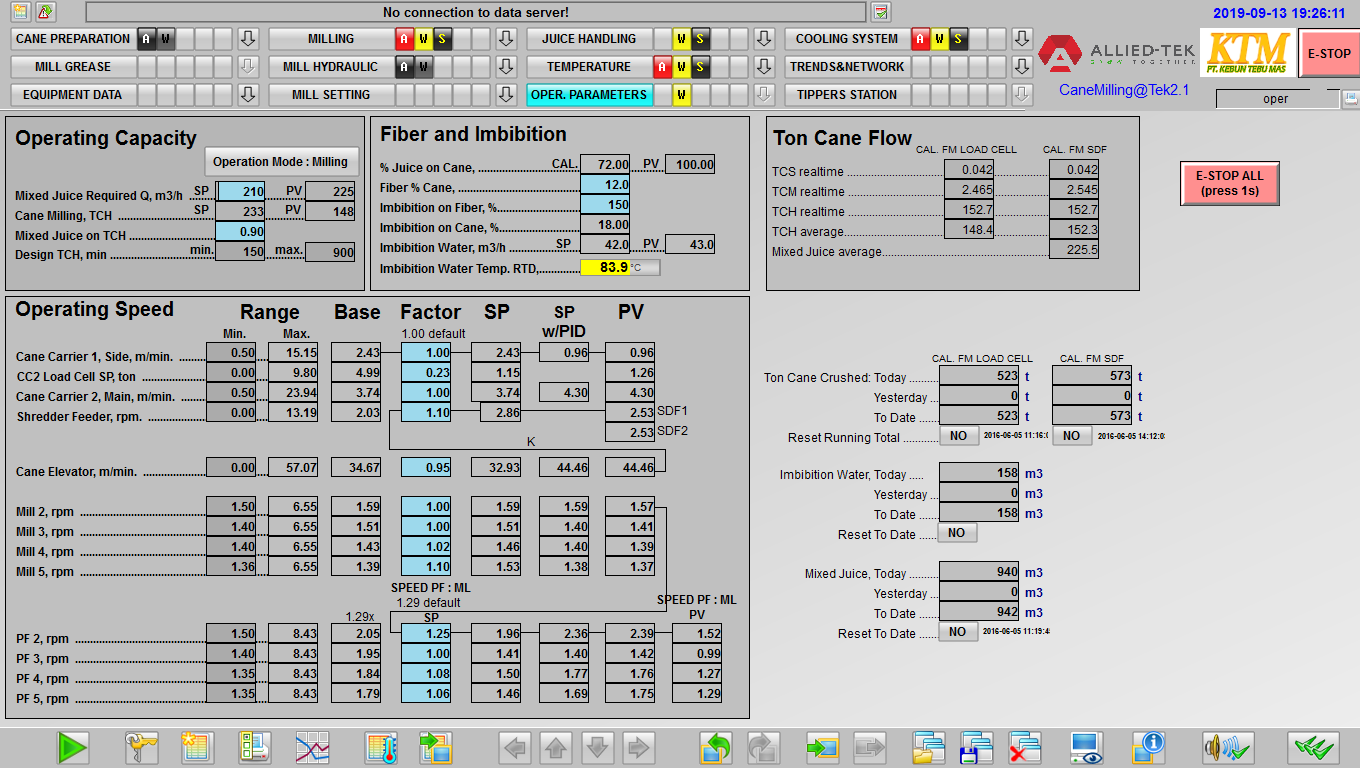

CaneMillingTek@xxx3.0 ::: High Efficiency Extraction

Equipment Manufacturing / In-House Design & Technology

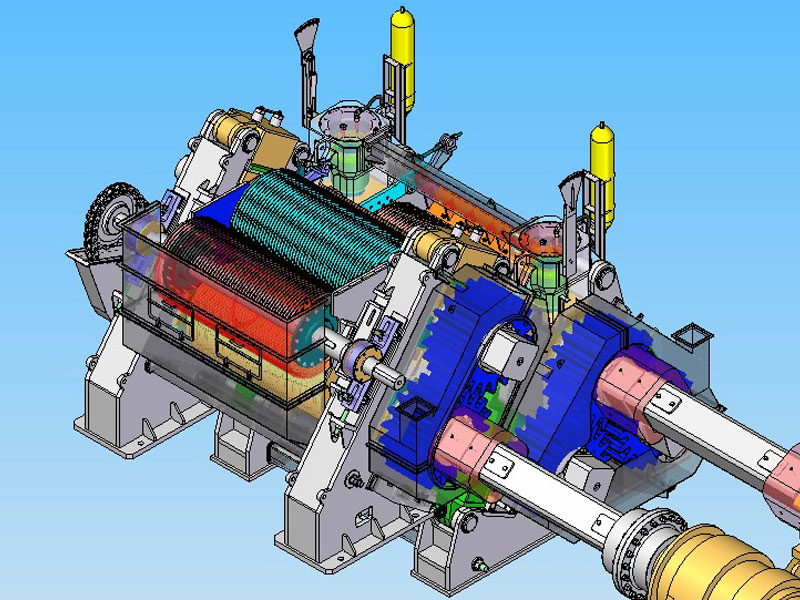

CANE ROLLR MILL

Standard MODEL Roll Dia.x Length., mm. Capacity, TCD (4-R / 6-R)

4179 1,050 x 2,000 5,000 / 10,000

4587 1,150 x 2,200 8,000 / 15,000

4995 1,250 x 2,400 10,000 / 18,000

5303 1,350 x 2,600 12,000 / 22,000

Triangle Stress Type with Apex angle of 73 deg = good milling force on ROLLS

4-R Mill ( 3x Mill Rolls + 1x UFR) & 6-R Mill ( 3x Mill Rolls + 2x PF + 1xUFR)

High strength steel fabricated Mill., Hydraulics Pressure on Top Rolls

28Mn6 forged steel shaft ., cast iron shell., LBC3 bronze journal bearings

Power Saving Mills either Individual Drives / Single Drives by AC Motors

Milling at 2,500 psi achieving pol ext. upto 97.5% upon operated by Software.

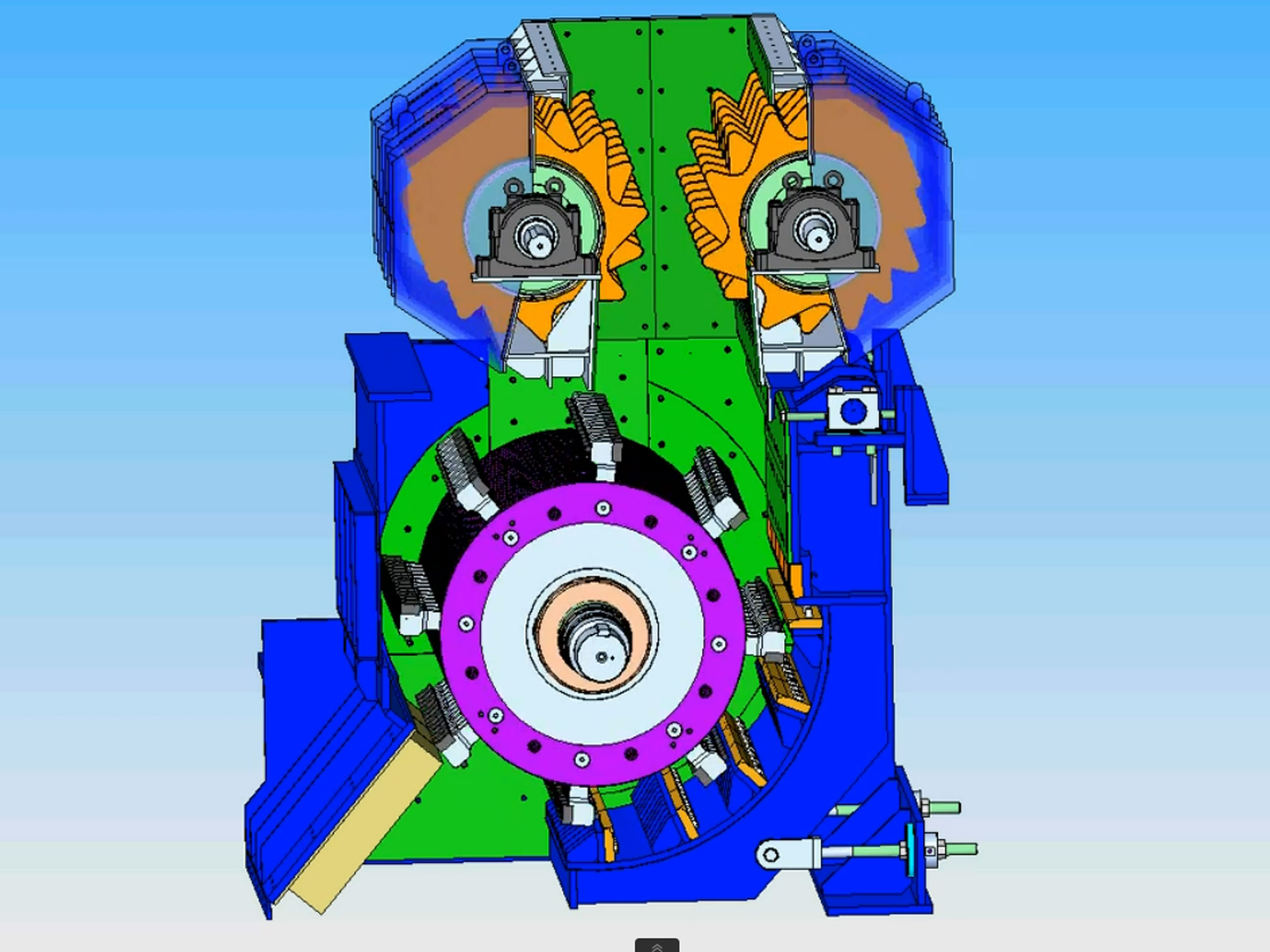

CANE SHREDDER

Model Tip Dia.x Width., mm. Capacity, TCD Hammers ,RowxNos each Power,kW

SD1515 1,530 x 1,550 4,000 8 x 9 = 72 1,000

SD1517 1,530 x 1,720 5,000 8 x 10 = 80 1,400

SD1519 1,530 x 1,890 7,000 8 x 11 = 88 1,800

SD1816 1,830 x 1,632 6,000 8 x 8 = 64 2,000

SD1818 1,830 x 1,832 9,000 8 x 9 = 72 2,800

SD1820 1,830 x 2,042 12,000 8 x 10 = 80 4,000

SD1822 1,830 x 2,242 16,000 8 x 11 = 88 5,000

SD1824 1,830 x 2,442 20,000 8 x 12 = 96 6,000

SD1826 1,830 x 2,642 24,000 8 x 13 = 104 7,000

SD2126 2,130 x 2,642 28,000 12 x 13 = 156 9,000

Heavy Duty Swing Hammer Type CANE SHREDDER.

CANE KINFE

ROTARY SCREEN

CANE CARRIER

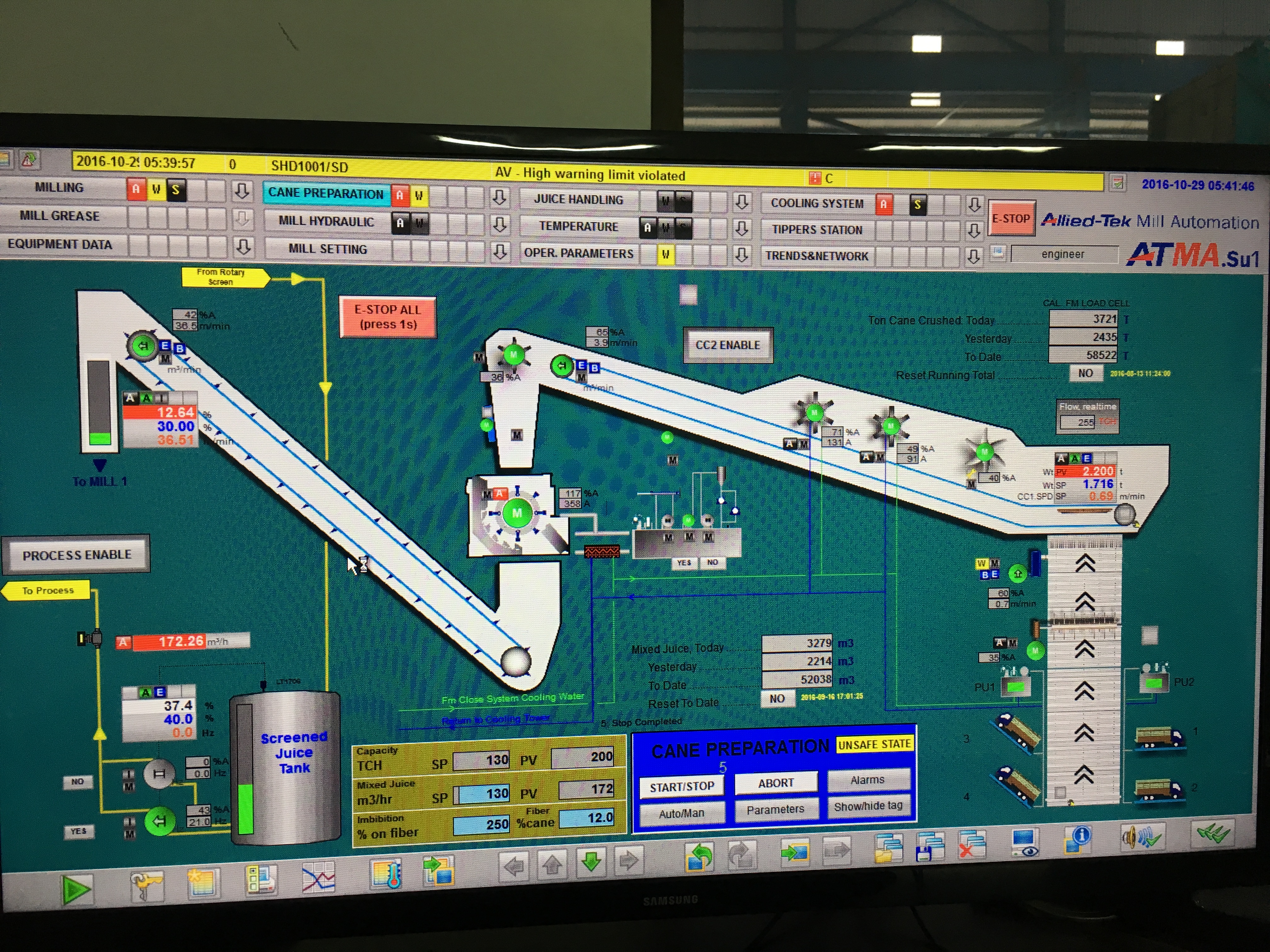

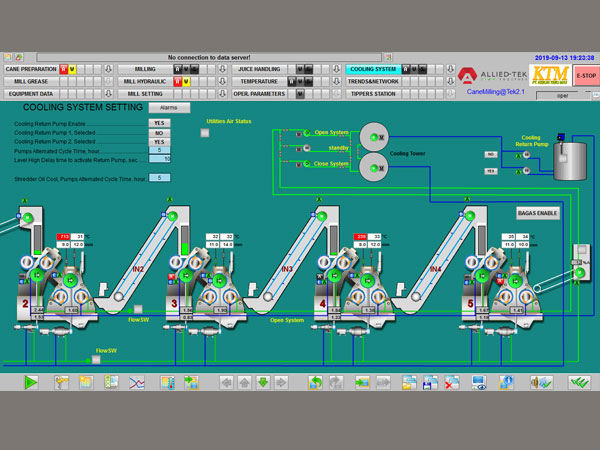

SOTFWARE-OPERATED

Cane Sugar Mill Parts Supply

Cane Shredder Hammers

Cane Knife

Shafts for Cane Mill